Costing view is used to determine the product cost. It can take various inputs, but for production the most important is the costing lot size. That means that an optimal lot size used for product cost estimate can be set here. Product can be produced in a 100 pieces lot or in a 3700 pieces lot; therefore the costing for those two situations are different. That is because there are some fixed expenses (time for setting up appropriate tool, mechanics work. In the first case, our product cost might be as high as 126 USD/pcs while in the other case, it could be 111 USD, which is remarkably different, so production has to try to plan their activities and stock levels of all materials in a plant in a way that our production lot size doesn’t vary too much and be as close to our optimal lot as possible.

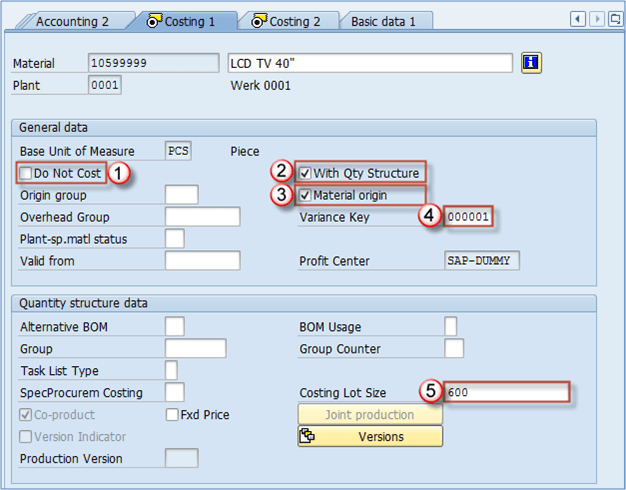

- Do Not Cost: no costing is estimated. Neither material cost nor sales order cost is created, just as procurement alternatives can’t be created as well. If you want costing at all, leave the field blank.

- With quantity structure: indicates if we want to use quantity structure data for cost estimating (lot size and other quantity information).

- Material origin: this indicates if material number should be assigned to cost element item in CO module.

- Variance key: determines how cost variance is calculated.

- Costing lot size: it is only useful if check box “With Qty structure” is checked. It determines the lot quantity used for a cost estimate calculation.