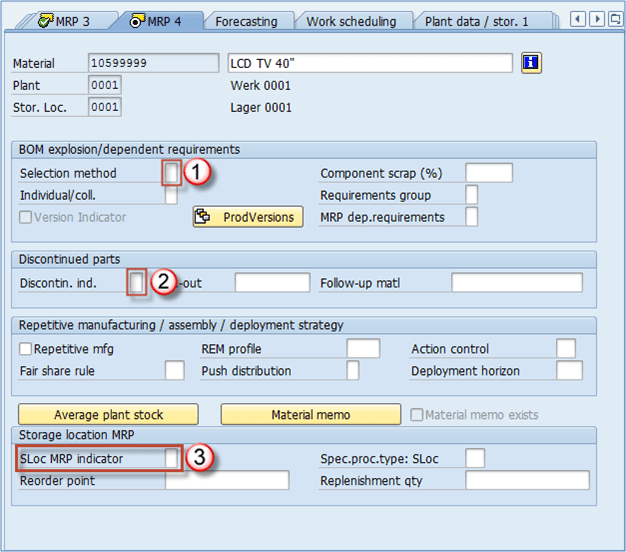

This is the only MRP view that is maintained on Plant / Storage location organizational level. It doesn’t contain as much valuable fields as previous, but there are three handy indicators that can be used to optimize processes in some modules.

- Selection method: if you are using BOMs (Bill Of Materials) for your production, you could govern with the selection of alternative BOMs with this field. You can set selection type by order quantity, production version, explosion date.

- Discontinued indicator: you can select the indicator for discontinued part as per requirements.

- SLoc MRP indicator: this is the most powerful indicator on this view. It tells us if our storage location (that we used in organizational levels screen – in this example 0001 – Lager 0001) is relevant for MRP. That is highly significant as it can reflect not only MRP but also ATP (available to promise) quantities. For example, if we use the default value (empty field), it means that our storage location is taken into account in our MRP runs. It is also taken into account in ATP so sales department can see the stock on this location available for sales activities. On the other hand, if you choose indicator 1 – Storage location stock excluded from MRP, this stock will not be taken into account for the MRP run, as well as it won’t be available to promise (ATP) to the customer, so it couldn’t be sold. If you choose indicator 2 – Manage storage location separately, it means that you want to manage this locations stock separately from plant stock (useful in some rare cases). The most obvious example for usage of this function is rejects storage location. When our LCD TV 40″ comes out of the production line it can be fully functional, or it might have a flaw. If it is ready for sales we will transfer it to our 0001 location and sales department will see that quantity available to be sold. Let’s say we produced 3000 TV sets. Out of that quantity there is 10 TV sets with some problems and our quality control department chooses that those cannot be sold, so these are sent to our location 0003 for rejects. In MRP 4 view, we have to maintain the indicator 1 for our rejects location 0003 as we don’t want sales department to see the stock as available. We only want the other 2900 pieces available that are on the 0001 location, for which we maintain empty field for this indicator (include in MRP/ATP).