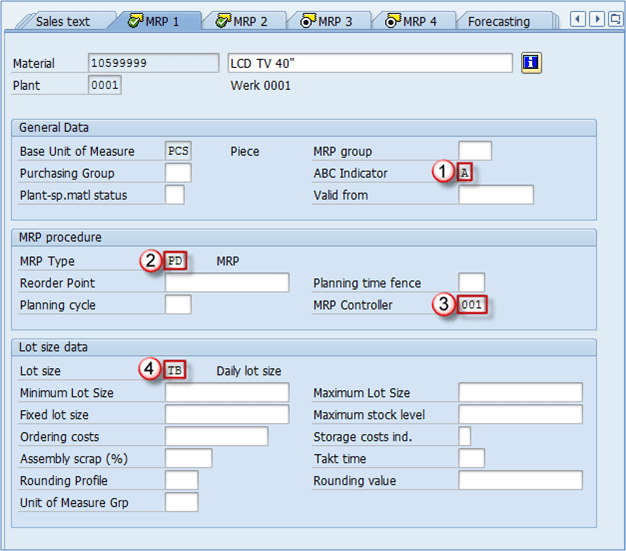

MRP views are maintained mostly for production purposes. This information is supplied by the appropriate MRP controllor or someone else from production planning team. The only mandatory field in MRP 1 View is Planning type. We will cover the most important fields used in a productive environment in more detail.

Purchasing group: this field is used to indicate which purchasing group is the default for purchasing this material. We haven’t maintained it yet as this is a finished product of our company, we don’t need it to be purchased at any time. We will set up this field for another material that needs to be purchased.

- ABC indicator: This is an indicator showing the importance of the material in terms of stock availability. Most of the companies use several ABC values, but most common are: A – the most important materials, they need to be available for sales in every moment customer requests it, B – less important materials that are often supposed to be available but the lack of this material can happen and is allowed, C – Least important materials. There can also be few more categories, N – new, material not yet tested on the market, so we don’t actually know if it’s going to be A, B or C yet. S – material that is produced only on customer request, and D – same as S with the difference that it has a certain quantity on stock just in case someone needs it ASAP, in production planning it is called a material safety stock.

- MRP type: there are various types of MRP that can be utilized. In this case, our MRP controller signalled that it should be PD – default MRP for most of the SAP installations.

- MRP controller: MRP controller responsible for production of this material, he manages all the data in these MRP views, along with the MRP results itself, production planning for this material etc. It is usual that the MRP controller provides the data for MRP views, or even in some organizational structures MRP controllers are maintaining these views on their own.

- Lot size: defines the procedure used by the system in order to calculate the procurement or production quantity of the material. Other fields in this view MRP group: this setting is used to group materials with same MRP control parameters which are, for example, the strategy group, the consumption mode, etc. If this field is not maintained, the system will use material group from Basic Data 1 when performing the MRP. Plant-Specific Material Status: If set, this indicates the usability of material in special functions, for example, material can be used for Testing or is going to be discontinued, so the MRP doesn’t take it into account when it runs. This setting could restrict the use of material in a particular function. Reorder Point: indicates at which stock level MRP should create a new order (either procurement or production order). Planning cycle: cycle of planning, it is defined in customizing and assigned to a material, it can represent a day on which the planning is performed. Minimum and Maximum lot size, Fixed lot size: used to indicate the boundaries for lot size, or a fixed quantity to be used. Ordering costs: fixed cost per order in company code currency, used to calculate the optimal lot size. Rounding Profile and Unit of Measure Group: like the fields in sales views, these are the same fields you can populate with rounding type to purchasing or production (if applicable). Rounding value: it is used in procurement for rounding the procurement quantity to a value of multiple of the number entered here.