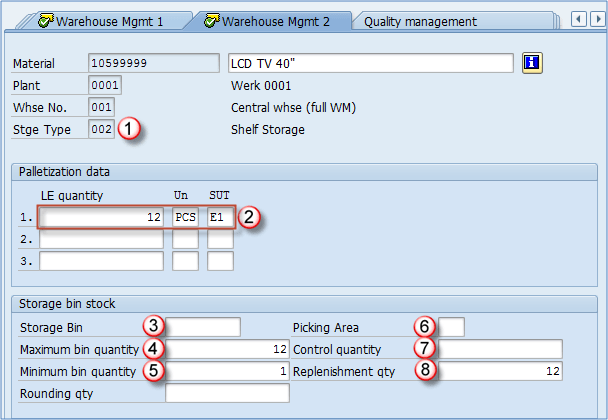

This view is maintainable on one more level than the previous view. Here are located pillarization data (quantities of material and types of pallets used) in the first section which isn’t maintained on storage type level but like previous view on warehouse number level. Lower section of the screen shows several fields that are storage type related settings.

- Storage type: the storage type for which we are extending/maintaining our material. In this case, we want our LCD TV to be stored at shelf storage (we have already selected this strategy in WM 1 View).

- Palletization data: this is information about how our material is packed onto different storage unit types. For example, our material is packed 12 pieces on Euro pallet 1m high (defined as E1 in our system).

- Storage bin: if we wanted to store our material in a predefined storage bin we would maintain this field. In this case, we want a system to propose a bin for our material every time we are executing putaway.

- Maximum bin quantity: this is usually a number that is maintained in palletization data, in our case 12 PCS. Used in check while placing the stock, system will not allow more than 12 PCS to be stored in one bin. Warehouse Management 2 View in material master

- Minimum bin quantity: this should be maintained only if replenishment is active for the storage type (mostly used in fixed bin storage types). In our case, if storage bin stock falls below 1 (no more TVs in the storage bin) system would request replenishment to be made, to fill the storage bin with another pallet. This is a very complex topic and requires more in-depth knowledge of warehouse management system in SAP.

- Picking area: like storage sections are grouping bins together in putaway process, picking areas group storage bins for picking process.

- Control quantity: for certain strategies (min/max quantity) utilized on storage type level, this is the quantity that signals the system that if the requested quantity for picking is higher than defined in this field, system should skip this storage type and move on to the next in our stock removal strategy. This is used in cases where we want to pick small quantities of material from one type of storage, and large quantities from another storage type.

- Replenishment quantity: when system determines that replenishment of our bin is needed it will replenish with quantity in this field. We have defined that we want replenishment when stock falls to zero, and we want it to be replenished by entire pallet – 12 pieces.